REINFORCEMENT

we provide high quality services

Chopped Strands

Our chopped strands are designed to reinforce thermoplastics through TP compounding and injection molding processes.

They provide key benefits for production productivity and high-performance Composite components including outstanding mechanicals, sustainability properties and complex design with a high degree of function integration.

They are used for various end-use markets: transportation, electrical and electronics, consumer goods.

Product Reference List :

979:

979 is a high performance chopped strand reinforcement engineered for optimum performance in BMC compression, injection and transfer molding applications. 979 sizing is specially formulated for maximum compatibility with polyester and vinylester resin systems. 979 chopped strand reinforcements can be used in a wide variety of applications including appliance components, automotive headlight reflectors and valve covers; electrical junction boxes and switch components; hand tool housing, sinks and countertops.

Multi End Rovings

Owens Corning pioneered the development of glass fi ber roving more than 50 years ago and continues to be the leading producer of this versatile product. OC® Multi-End Continuous Rovings are made globally using the most advanced equipment, innovative surface chemistry and a major commitment to statistical process control. The company’s quality management programs meet the requirements of ISO 9002 and assure the production of quality products that meet customer cost and performance needs.

Features & Benefits :

- Meets or exceeds all the current OEM Class A surface specifications.

- Excellent mold flowability to allow production of large class A parts with a low defect rate.

- SMC Rovings.

- Fast wet-through.

- Low squeeze-out to maximize line speed and maintain tight sheet weight tolerances.

- Superior runability.

- Optimized to maximize equipment uptime.

- Low static and fuzz.

- Chemistries are specifically designed to virtually eliminate static and reduce fuzz and fly.

- Excellent chopability.

- Products Can Be Chopped Cleanly With Minimal Blade And Cot Wear.

- Excellent Dispersion.

- Flat Dispersion Characteristics Eliminate Clumping.

- Excellent Laminate Mechanical Properties.

- Meet Or Exceeds Physical Property Requirements For A Broad Range Of Applications.

- Optimum Package Weight.

- More Product Per Package And Pallet Allows Longer Run Time Before More Material Is Needed At The Chopping Station.

Packaging :

Rovings are available in a single end internal pull package. Each pallet contains four layers with 12 doffs per layer (48 per pallet) or three layers with 12 doffs per layer (36 per pallet). All pallets are stretch wrapped. Doffs are available in weights between 17 kg (37.4 lb.) and 29.4 kg (65 lb.). Doffs can be placed in Bulk-Pak or Creel-Pak format in the packaging. For Bulk-Pak pallets, the core ends of all doffs are slip knotted. All Creel-Pak pallets have ends that are spliced together. One-, two-, four-, eight- and 12-end run-outs are available dependent upon specifi c customer requirements

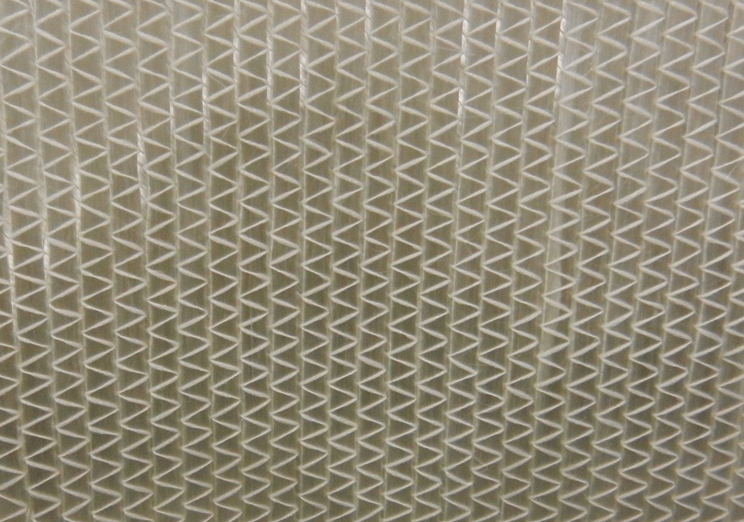

Fabric

Types Of Fabric :

- Glass Fiber Woven Roving.

- Multiaxial Fabric.

- Flow Mat.

- Special Fabric.

- Narrow Width Fabric & Mat.

- Biaxial Fabrics.

- Stitch Mat.

- Combination Mat.

Applications :

- Wind power.

- Aviation.

- Transportation.

- Railway Vehicles.

- Rotor Blades.

- Generator housings.

- Pultrusion.

- Sports and leisure equipment.

- Rowing boards.

- Winter sports equipment.

- Surf boards.

- Construction industry.

- Thermal insulation.

- Fire protection.

- Cured in place pipes.

- Automotive.

- Pressure pipes.

- Electrical insulation.

Single-End Rovings

Product Description:

Single-End Rovings are reinforcement products for filament winding, long-fiber thermoplastics, pultrusion, knitting and weaving applications with polyester (UP), vinylester (VE), epoxy (EP), phenolic (PN), polypropylene (PP), polyamide (PA) resin systems. Single-End Rovings are produced by pulling individual fibers directly from the bushing and winding them onto a roving package ready for shipment. The uniform distribution of a proprietary sizing system ensures an excellent resin-to-glass binding through uniform distribution of the binding agent.

Features & Benefits :

- Superior processing.

- Optimized to maximize equipment uptime.

- Fast wet-out.

- Increased productivity.

- Optimum package and pallet weight.

- Better productivity, less storage space, fewer pallet changes.

- Excellent laminate mechanical properties.

- Meets or exceeds physical properties requirements for a broad range of applications.

- Excellent packaging run out and transfer.

- More complete gas utilization and reduced labor costs.

Packaging :

Rovings are available in a single-end internal-pull package. Each pallet weighed about 1 ton. Pallets are stretch wrapped for load stability. All doffs are wrapped with Tack-Pak® transport. Full doffs are available in weights of 20 kg (45 lb.) and 40 kg (88 lb.) regionally and they can be packaged in bulk or Creel-Pak® forma

Notes: Data Sheets for SE 1200

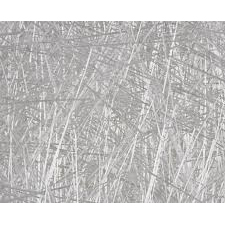

Chopped Strand Mat:

Mat is use with Unsaturated Polyester, Vinyl Ester resin systems in hand lay up Applications including automotive parts, boats, Chemical Tanks and Pools.

Applications :

- Chemical.

- Consumer Goods > Other Open or Closed Mold.

- Consumer Goods > Swimming Pools.

- Industrial and Corrosion.

- OEM (Original Equipment Manufacturer).

- Oil and Gas.

- Pipes and Tanks.

- Transportation > Automotive > Interior > Semi-Structural.

- Transportation > Marine.

Nominal Mat Weight In Gsm :

- 225 GSM

- 300 GSM

- 450 GSM

Roll width: 1250mm and 1040mm

Packaging & Labelling :

Each roll is wound on a 76mm cardboard tube and placed inside a polyethylene bag and cardboard box. The boxed product is then placed vertically on a wooden pallet and shrink-wrapped for stability and protection.

Each roll bears a label detailing the product description, product code, nominal weight, roll width, roll number and date of manufacture.